Description

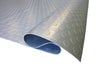

Unveiling the Advantages of Ultra Thin Silicone Sheet: Redefining Precision and Performance in Engineering

Characteristics

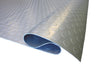

Ultra-thin silicone sheet embodies a host of features that set it apart as a cutting-edge material for precision applications:

Feather-Light Thickness

As the name suggests, ultra-thin silicone sheet is characterized by its incredibly thin profile, measuring in micrometers or millimeters. This extreme thinness allows for precise placement and adherence in applications where space is at a premium, without sacrificing performance.

Exceptional Flexibility

Despite its thinness, ultra-thin silicone sheet maintains remarkable flexibility and elasticity. This property enables it to conform seamlessly to irregular surfaces and intricate geometries, ensuring a snug fit and optimal functionality in even the most demanding environments.

High-Temperature Stability

Silicone rubber is renowned for its exceptional thermal resistance, and ultra-thin silicone sheet is no exception. Withstanding temperatures ranging from -45°C to +200°C, this material remains stable and reliable even in extreme heat or cold, making it suitable for a wide range of temperature-sensitive applications.

Superior Electrical Insulation

Ultra-thin silicone sheet boasts excellent electrical insulation properties, making it ideal for use in electronic devices, circuitry, and electrical components. Its dielectric strength and resistance to electrical breakdown ensure reliable performance and safety in high-voltage applications.

Applications

The versatility and precision afforded by ultra-thin silicone sheet render it indispensable in a myriad of applications across various industries, including:

Electronic Devices

From smartphones to wearable gadgets, ultra-thin silicone sheet serves as a vital component in the assembly and insulation of electronic devices, providing thermal management, moisture resistance, and electrical insulation.

Medical Devices

In the medical field, ultra-thin silicone sheet finds applications in devices such as catheters, implants, and surgical instruments, where biocompatibility, flexibility, and precise dimensions are essential for patient safety and comfort.

Aerospace and Automotive

Ultra-thin silicone sheet plays a crucial role in aerospace and automotive applications, where lightweight construction, vibration damping, and thermal management are critical for performance and reliability.

Microfluidics and Lab-on-a-Chip

In microfluidic devices and lab-on-a-chip systems, ultra-thin silicone sheet serves as a versatile substrate for creating precise channels, valves, and membranes, enabling precise manipulation and analysis of tiny volumes of fluids and particles.

Conclusion

Ultra-thin silicone sheet stands as a testament to the ingenuity and innovation driving the field of precision engineering. With its feather-light thickness, exceptional flexibility, high-temperature stability, and superior electrical insulation properties, this groundbreaking material is revolutionizing a wide range of industries, from electronics to healthcare to aerospace. As technology continues to advance and demands for precision escalate, ultra-thin silicone sheet remains at the forefront, enabling engineers and manufacturers to push the boundaries of what's possible in the pursuit of precision and performance.