Description

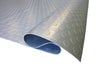

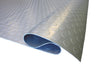

Harnessing the Power of Precision: Vacuum Grade Silicone Sheet Redefining Sealing Solutions

Characteristics

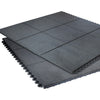

Vacuum grade silicone sheet embodies a host of characteristics that make it an indispensable component in vacuum systems:

Ultra-Pure Composition

Manufactured using stringent processes and premium-grade silicone polymers, vacuum grade silicone sheet boasts exceptional purity, minimizing the risk of outgassing and contamination in high-vacuum environments. This purity ensures the integrity of vacuum systems, making it ideal for critical applications in aerospace, semiconductor fabrication, and scientific research.

High-Temperature Resistance

Operating in high-vacuum environments often entails exposure to extreme temperatures. Vacuum grade silicone sheet rises to the challenge with its exceptional thermal stability, capable of withstanding temperatures ranging from -60°C to 230°C (-76°F to 446°F) without compromising its sealing performance. This resilience ensures reliable sealing even in the most demanding thermal conditions.

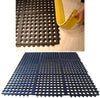

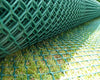

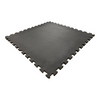

Excellent Flexibility and Elasticity

Despite its robustness, vacuum grade silicone sheet remains highly flexible and elastic, enabling it to conform seamlessly to irregular surfaces and maintain a tight seal under varying pressures. This flexibility minimizes the risk of leaks and ensures optimal performance in vacuum chambers and systems.

Chemical Compatibility

Vacuum grade silicone sheet exhibits excellent resistance to a wide range of chemicals, including acids, bases, solvents, and gases commonly encountered in vacuum environments. This chemical compatibility enhances the longevity of seals and gaskets, minimizing maintenance requirements and downtime in critical applications.

Applications

The versatility and reliability of vacuum grade silicone sheet render it indispensable across a myriad of applications in vacuum technology and beyond:

Aerospace and Space Exploration

In aerospace applications, vacuum grade silicone sheet serves as a vital component in sealing critical systems, such as propulsion systems, satellite components, and spacecraft instrumentation, where precision and reliability are paramount.

Semiconductor Manufacturing

Vacuum grade silicone sheet finds extensive use in semiconductor fabrication processes, including wafer handling, vacuum chamber sealing, and wafer bonding, where ultra-high vacuum conditions are necessary to ensure the integrity of microelectronic devices.

Scientific Research

In scientific research laboratories, vacuum grade silicone sheet plays a crucial role in creating vacuum-tight seals for experimental chambers, vacuum ovens, and analytical instruments, facilitating a wide range of research endeavors in physics, chemistry, and materials science.

Pharmaceutical and Biotechnology

Vacuum grade silicone sheet is utilized in pharmaceutical and biotechnology industries for sealing and gasketing applications in vacuum drying, freeze-drying, and lyophilization processes, ensuring the integrity of sensitive pharmaceutical products and biological samples.

Conclusion

Vacuum grade silicone sheet stands as a testament to the relentless pursuit of precision and reliability in vacuum technology. With its ultra-pure composition, high-temperature resistance, excellent flexibility, and chemical compatibility, this specialized material continues to redefine sealing solutions in critical applications across industries. As advancements in vacuum technology propel us towards new frontiers in aerospace, semiconductor manufacturing, scientific research, and beyond, vacuum grade silicone sheet remains at the forefront, enabling engineers and researchers to push the boundaries of what's possible in the pursuit of precision and performance in vacuum systems.