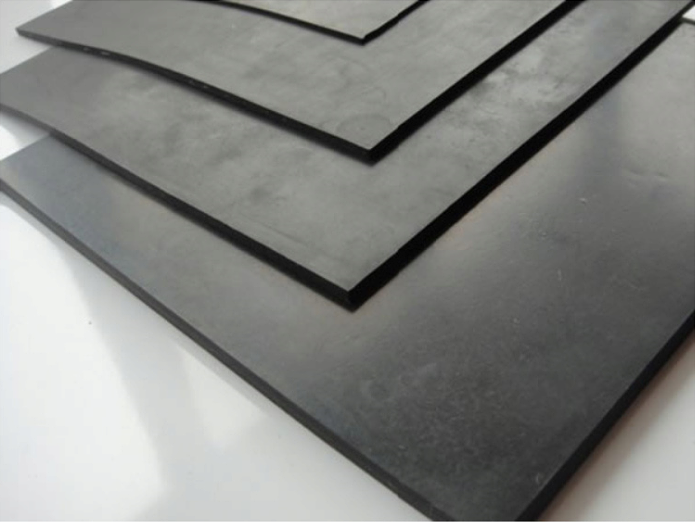

EPDM Rubber Sheet 1.5-25mm | Weather & Chemical Resistant | Cut to Length UK | Best Seller

SKU: RBRMTDR3211

Pay in 3 interest-free instalments of £18.96 with Shop Pay

Product Specifications

- Free UK delivery on all orders

- Industrial grade

- Chemical resistant

- Multiple thicknesses

- Gaskets and seals

Trusted by Leading Companies

Description

EPDM Rubber Sheet - Superior Weather & Chemical Resistance | Best Seller

★ One of our best-selling rubber sheets - trusted by 500+ UK businesses ★

Premium quality EPDM (Ethylene Propylene Diene Monomer) rubber sheet engineered for demanding industrial, commercial and domestic applications. Available in thicknesses from 1.5mm to 25mm, our 1400mm wide EPDM sheets deliver exceptional performance in harsh environments.

Product Code: RBRMTDR3211-3220 Series | Sold by the linear metre (meter) | 4.3★ rated by verified buyers

Why Choose EPDM Rubber Sheet?

- Outstanding Weather Resistance: Unaffected by UV rays, ozone, rain, snow or temperature extremes (-40°C to +120°C / -40°F to +248°F)

- Superior Chemical Compatibility: Resistant to acids, alkalis, ketones and most solvents

- Long Service Life: Maintains integrity for 20+ years in outdoor applications

- Flexible & Elastic: 60 ± 5 Shore A hardness - conforms to irregular surfaces while maintaining seal integrity

- Cost-Effective: Minimal maintenance requirements reduce total ownership costs

- High Performance: Tensile strength ≥10 MPa, elongation ≥400%

Common Applications

Our EPDM rubber sheet is the material of choice for:

- Roofing & Waterproofing: Flat roof membranes, weatherproofing, building seals

- Water Features: Pond liners, water garden applications, aquatic installations

- Industrial Sealing: Gaskets, O-rings, industrial seals, flange gaskets

- HVAC Systems: Heating, ventilation, air conditioning components

- Automotive: Weatherstripping, door seals, window seals

- Vibration Control: Dampening pads, anti-vibration mounts, machinery isolation

- Electrical: Insulation applications, cable protection

- Marine: Boat seals, marine equipment, deck applications

Technical Specifications

| Property | Value |

|---|---|

| Material | EPDM (Ethylene Propylene Diene Monomer) - M-Class Rubber |

| Width | 1400mm (55 inches) |

| Thickness Range | 1.5mm, 2mm, 2.5mm, 3mm, 8mm, 10mm, 12mm, 15mm, 20mm, 25mm |

| Temperature Range | -40°C to +120°C (-40°F to +248°F) |

| Hardness | 60 ± 5 Shore A (Medium hardness) |

| Tensile Strength | ≥10 MPa |

| Elongation at Break | ≥400% |

| Colour | Black |

| UV Resistance | Excellent - No degradation from sunlight |

| Ozone Resistance | Excellent - Superior to natural rubber |

| Chemical Resistance | Acids, alkalis, ketones, polar solvents |

| Oil Resistance | Not suitable for petroleum oils (use Nitrile instead) |

Which Thickness Do I Need? - Selection Guide

- 1.5mm - 3mm (Light Duty): Gaskets, light-duty seals, DIY projects, pond liners, craft applications, thin weatherstripping. Price from £34.94/metre

- 5mm - 8mm (Medium Duty): Domestic flat roofing, workshop matting, moderate vibration dampening, general purpose sealing. Price from £164.50/metre

- 10mm - 15mm (Heavy Duty): Commercial roofing membranes, heavy-duty seals, industrial flooring, high-performance gaskets. Price from £205.87/metre

- 20mm - 25mm (Extreme Duty): Extreme vibration isolation, heavy machinery mounting, structural applications, maximum durability. Price from £401.87/metre

EPDM vs Other Rubber Types - Comparison Guide

EPDM vs General Purpose Rubber: EPDM offers superior weather and ozone resistance, making it ideal for outdoor applications where standard rubber would degrade.

EPDM vs SBR Rubber: While SBR is more economical, EPDM excels in UV stability and temperature extremes. Choose EPDM for roofing and outdoor exposure.

EPDM vs Nitrile Rubber: For oil and fuel resistance, choose nitrile rubber sheets. For weather resistance, EPDM is superior.

EPDM vs Neoprene: Neoprene offers better oil resistance, but EPDM provides better weather resistance and is more cost-effective for outdoor applications.

Temperature & Environment Applications

Our EPDM rubber sheet performs exceptionally across extreme temperature ranges:

- Cold Resistant Rubber Sheet: Maintains flexibility down to -40°C - perfect for freezer applications, cold storage seals, and arctic environments

- Heat Resistant Rubber Sheet: Stable up to +120°C - ideal for engine compartments, hot water systems, and high-temperature gaskets

- Extreme Temperature Rubber: The wide -40°C to +120°C range makes EPDM suitable for applications with dramatic temperature fluctuations

Industry-Specific Applications

Explore our specialized collections for your industry:

- Construction & Roofing: Featured in our Rubber Matting By Industry collection

- Home Improvement: Perfect for DIY projects - see Rubber Matting For Home

- Application-Specific: Browse by use case in Rubber Matting By Application

Frequently Asked Questions

Is EPDM rubber UV resistant?

Yes, EPDM has excellent UV resistance and won't degrade from sunlight exposure. Unlike natural rubber or SBR, EPDM maintains its properties for 20+ years outdoors, making it perfect for roofing membranes and outdoor sealing applications.

What thickness EPDM for flat roofing?

For domestic flat roofs, 3-5mm thickness is typically sufficient. Commercial applications should use 5-10mm thickness for enhanced durability and puncture resistance. For high-traffic roofs, consider 10mm+ thickness.

Can EPDM withstand chemicals?

EPDM resists most acids, alkalis, ketones, and polar solvents including brake fluid, phosphate esters, and diluted acids. However, it's not suitable for petroleum oils, gasoline, or hydrocarbon fuels - use nitrile rubber for those applications.

How do I cut EPDM rubber sheet?

Use a sharp utility knife with a fresh blade and a metal straight edge. Score the rubber multiple times along your cutting line rather than attempting to cut through in one pass. For thicker sheets (10mm+), you may need to score from both sides for clean edges.

What's the lifespan of EPDM rubber?

When properly installed, EPDM rubber can last 20-50 years in outdoor applications with minimal degradation. Its resistance to UV, ozone, and weathering ensures long-term performance without cracking or deterioration.

What is Shore A hardness and why does it matter?

Shore A measures rubber hardness. Our 60 Shore A EPDM is medium hardness - firm enough for structural integrity but flexible enough to conform to surfaces and create effective seals. This makes it ideal for gaskets and sealing applications.

Is EPDM rubber suitable for pond liners?

Yes, EPDM is excellent for pond liners. It's fish-safe, UV resistant, and flexible enough to conform to pond shapes. Use 2-3mm thickness for small garden ponds, 5mm+ for larger installations.

Can I use EPDM rubber sheet for automotive applications?

Absolutely. EPDM is widely used in automotive weatherstripping, door seals, and window seals due to its weather resistance. However, avoid contact with engine oils - use nitrile rubber for oil-exposed areas.

Alternative Product Codes & Cross-References

Our EPDM rubber sheet series (SKU: RBRMTDR3211-3220) is compatible with and can replace many industry-standard EPDM specifications. If you're looking for alternatives to competitor products or need to match specific part numbers, contact our technical team for cross-reference assistance.

Environmental Sustainability

EPDM is a synthetic rubber with lower environmental impact than petroleum-based alternatives. It's derived from ethylene, propylene, and natural gas feedstocks. EPDM is fully recyclable at end-of-life, and its exceptional longevity (20-50 years) reduces replacement frequency and waste.

Winter 2026 Special - Roofing Season

January-March 2026: Perfect timing for winter roofing repairs and spring preparation. EPDM rubber sheet remains flexible even in cold weather, making it ideal for winter installation. Prepare your flat roof for spring rains with our weather-resistant EPDM membrane.

UK Delivery & Trade Accounts

Fast Dispatch: In-stock items ship same day for next-day UK delivery. Made-to-order thicknesses typically ship within 3-5 working days.

Trade Accounts Available: Regular customers benefit from preferential pricing, credit terms, and priority processing. Contact us to set up your trade account.

Cut-to-Length Service: Need custom sizing? We offer precision cutting services. Contact our team with your requirements.

Bulk Discounts: Volume pricing available for large orders. Perfect for contractors, builders, and industrial users.

Technical Support

Our experienced technical team can help you:

- Select the correct thickness for your application

- Provide installation guidance and best practices

- Recommend adhesives and fixing methods

- Answer chemical compatibility questions

- Assist with custom sizing requirements

Need help selecting the right EPDM rubber sheet? Contact our technical team for expert advice on thickness selection, application suitability, and installation methods.

Order your premium EPDM rubber sheet by the linear metre (meter) today - trusted by professionals across the UK.

EPDM Rubber Sheet 1.5-25mm | Weather & Chemical Resistant | Cut to Length UK | Best Seller

Frequently Bought Together...

Frequently Bought Together

Customers who viewed this also viewed these products